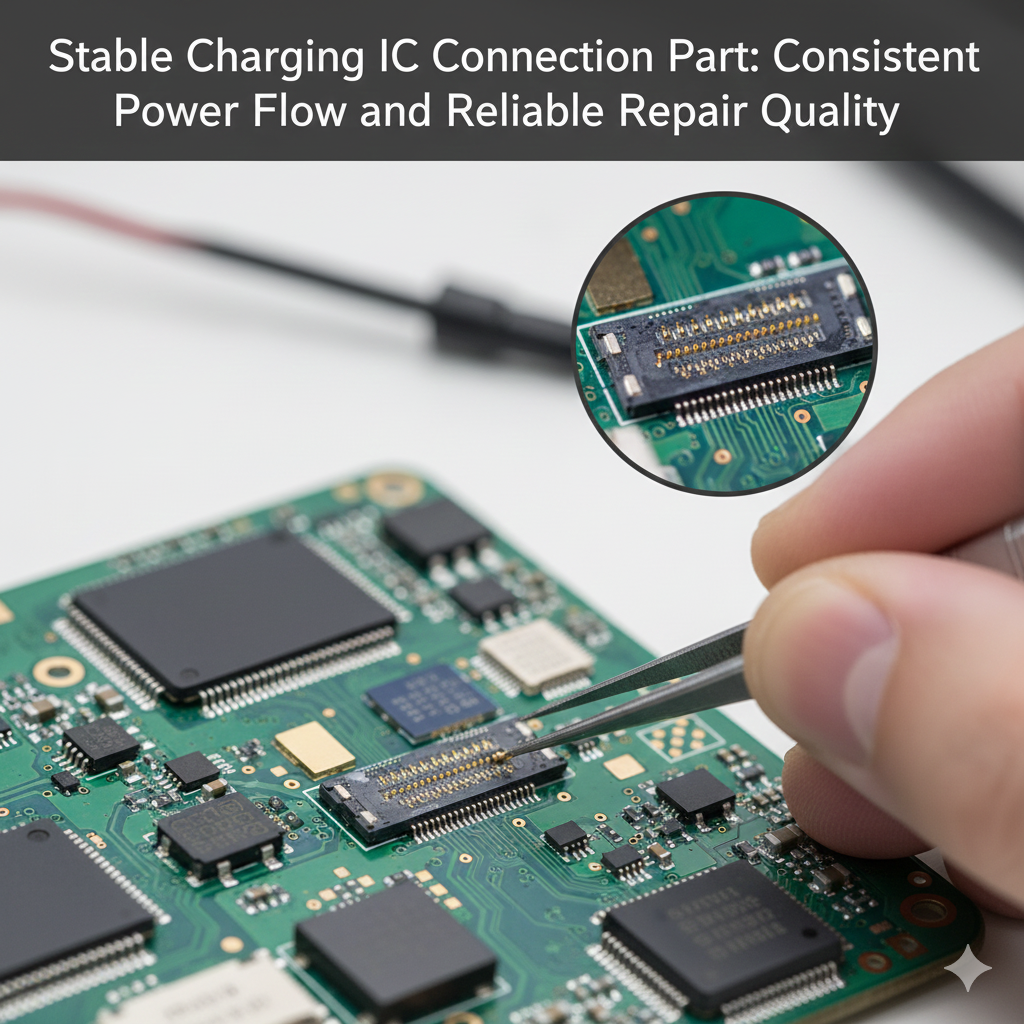

Stable Charging IC Connection Part: Consistent Power Flow and Reliable Repair Quality

When Power Becomes the Weak Link in a Repair

In many “successful” phone repairs, the most common post-service complaint isn’t about the display—it’s about charging.

The phone connects, disconnects, or charges slowly. The charging icon flickers. The battery percentage jumps erratically.

Most of these problems stem not from the power IC itself, but from unstable connection parts—flex cables, solder joints, or connectors that fail to deliver clean voltage.

For technicians, these subtle faults often turn into repeat repairs and customer dissatisfaction.

That’s why the foundation of reliable repair lies in a stable charging IC connection part—a component engineered for steady power transmission and mechanical durability.

Why Connection Stability Matters More Than Power Output

The charging IC manages voltage regulation, but it relies entirely on the integrity of its connection part to perform safely.

Even minor fluctuations in resistance or current transfer can trigger:

-

Overheating and IC burnout.

-

Inconsistent charging detection by the motherboard.

-

Battery protection circuit errors.

-

Shortened lifespan of replacement boards.

In short, the connection part acts as the bridge of stability—if that bridge weakens, the entire circuit suffers.

Comparing Common Replacement Parts vs. CPG Stable Connection Components

| Parameter | Generic Connector | CPG Stable Charging IC Connection Part |

|---|---|---|

| Contact Resistance | Variable | Constant (<20 mΩ) |

| Heat Dissipation | Poor | Optimized copper alloy path |

| Flexibility | Weak under bending | Reinforced structure |

| QC Testing | Visual only | Electrical and mechanical |

| Failure Rate | 6–10% | <1% per batch |

The data speaks for itself—CPG parts provide tight connection precision, verified electrical conductivity, and long-term resistance against oxidation or signal interference.

Inside CPG’s Design and Testing Process

Each CPG charging IC connection part undergoes multi-step testing before shipment:

-

Resistance Consistency Check

Ensures uniform voltage drop across all connector pins. -

Thermal Load Simulation

Runs a 2-hour high-current test to verify no excessive heat buildup under standard 5V–9V load. -

Signal Interference Test

Checks electromagnetic stability for consistent data and power transmission. -

Mechanical Flex Test

10,000 bending cycles validate durability under repeated assembly stress. -

Visual and Microscopic Inspection

Confirms solder alignment, pin elasticity, and plating integrity.

Every product passes through an automated traceability system—each connector or flex part includes a batch ID and testing report, ensuring every shipment’s quality is measurable, not promised.

Advantages for Repair Technicians and Distributors

-

Stable charging recognition across all devices.

-

Reduced overheating risk during high-load charging.

-

Longer service life, even in frequently charged devices.

-

Pre-tested reliability, lowering return and warranty costs.

-

OEM-standard fit, ensuring seamless installation with no solder correction.

For large-scale distributors or refurbishment facilities, CPG’s consistent quality means less after-sales stress and higher customer retention.

Common Scenarios Where Stability Saves the Repair

-

Water-damaged phones with corroded charging pathways.

-

Refurbished devices needing reliable power calibration.

-

High-load users (delivery, GPS, or gaming devices) demanding thermal control.

-

Repair centers offering warranty-backed charging board replacements.

In all these cases, stable IC connection parts are the difference between a temporary fix and a lasting repair.

Choosing the Right Charging IC Connection Part

When sourcing replacement parts, technicians should verify:

-

Contact resistance data (≤20 mΩ) per report.

-

Heat tolerance rating (up to 80°C) for sustained charging.

-

Material composition, preferring copper-nickel alloy over pure brass.

-

ESD-safe packaging to prevent microstatic damage.

-

Traceability certification from the manufacturer.

CPG provides all five, combining mechanical resilience, electrical precision, and clear testing data for each batch.

Frequently Asked Questions (FAQ)

Q1: Can unstable connectors damage the charging IC?

Yes—unstable voltage causes overheating and eventual IC degradation.

Q2: How long do CPG charging IC connection parts last?

Each part is tested for 10,000 flex cycles and over 500 hours of thermal load.

Q3: Are these parts compatible with multiple brands?

Yes, available for iPhone, Huawei, Samsung, Xiaomi, and OPPO models.

Q4: Do they come with individual testing reports?

Yes. Each batch includes electrical and mechanical inspection data.

Power That Lasts, Confidence That Stays

Charging stability is not just about speed—it’s about trust.

With CPG’s stable charging IC connection parts, repair professionals and distributors gain consistent voltage transfer, verified testing data, and the reliability that defines premium service.

To request part specifications or purchase in bulk, visit CPG LCD’s homepage or reach our technical support team through the Contact Us page.