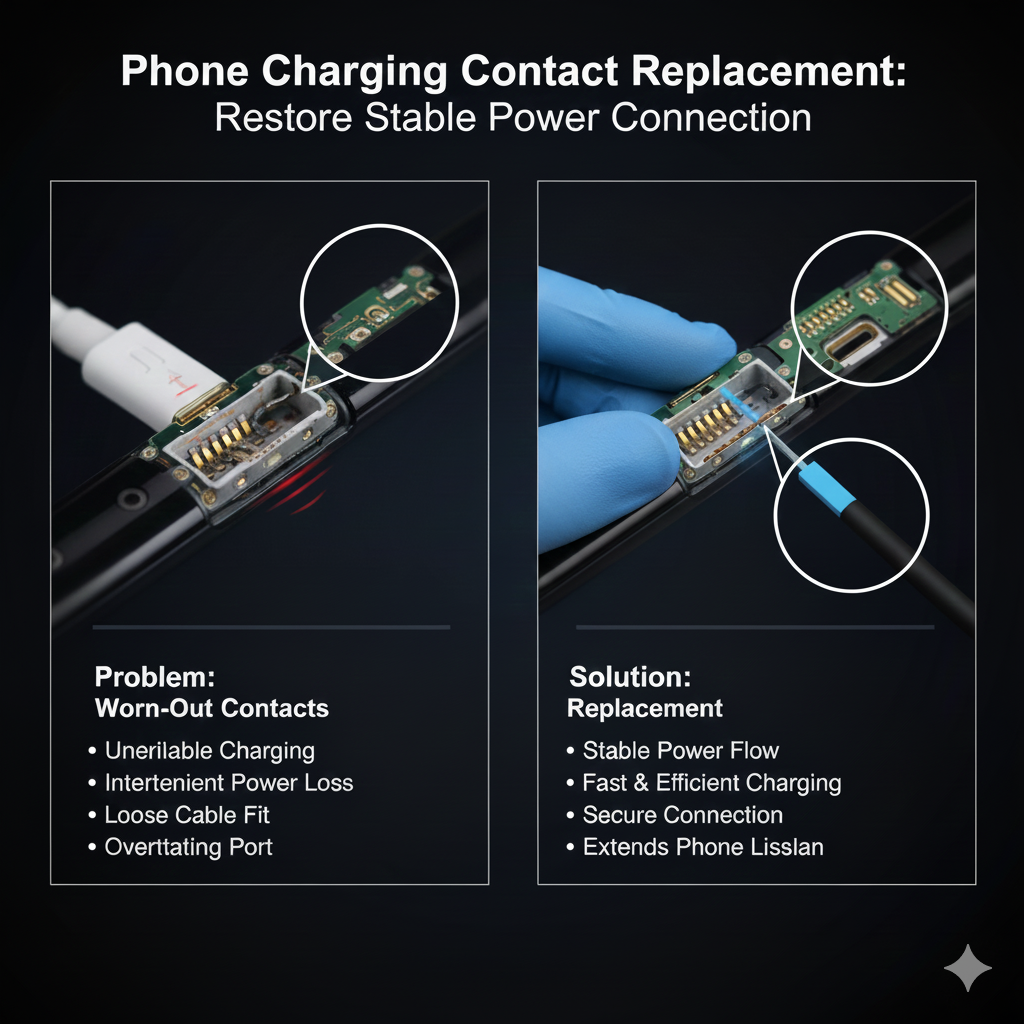

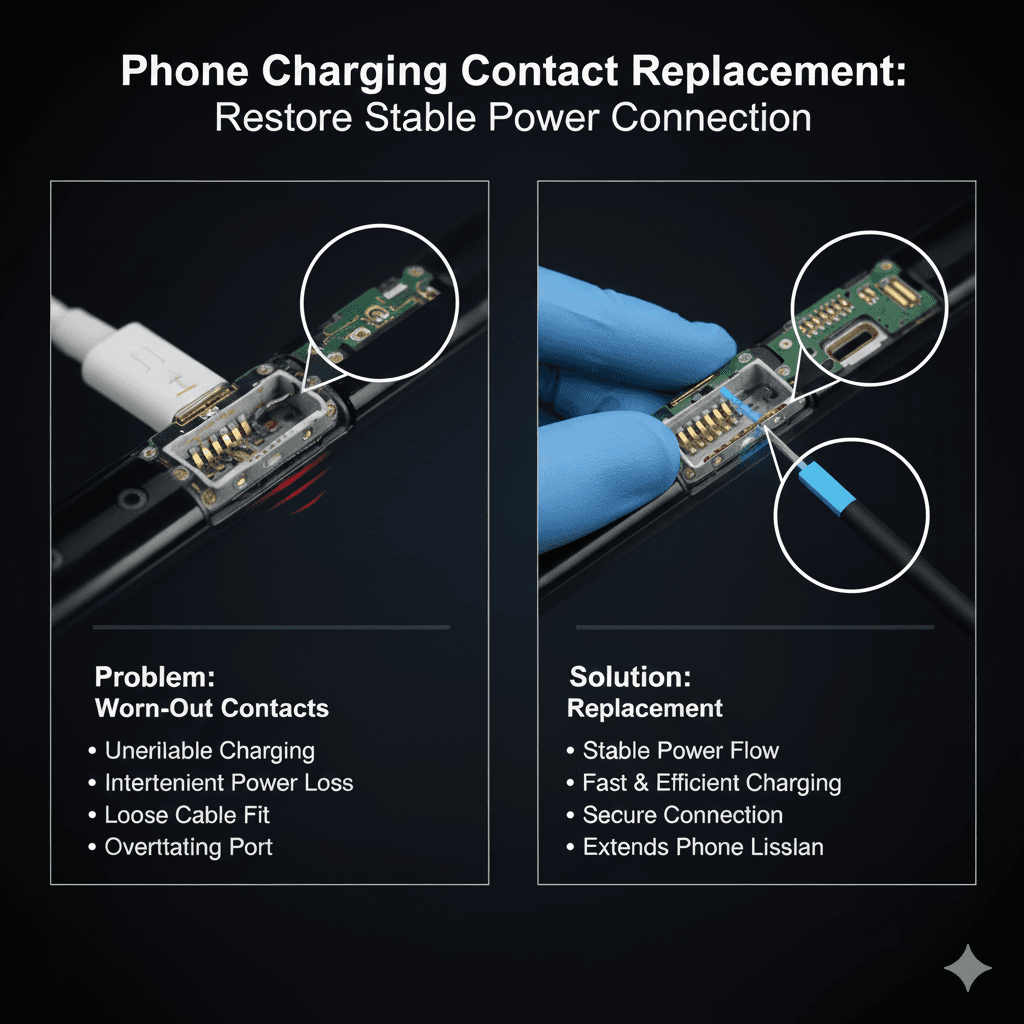

Phone Charging Contact Replacement: Restore Stable Power Connection

When a Loose Connection Becomes a Power Problem

For technicians, one of the most deceptive repair cases is when a phone intermittently charges—sometimes fine, sometimes dead.

Often, it’s not the port, not the cable, but the charging contact—the spring-loaded or soldered connection between the mainboard and charging flex.

Common symptoms include:

-

Charging stops when the phone moves slightly.

-

Unusual heating near the charging area.

-

Battery percentage fluctuates while charging.

-

No response when using data cables despite port replacement.

These issues arise because charging contacts wear, oxidize, or lose tension after thousands of compression cycles, especially in phones with modular charging boards.

Understanding the Charging Contact Assembly

Charging contacts act as the bridge between the charging port assembly and the main power distribution line.

Each set typically includes:

-

VBUS pins for voltage input.

-

GND pins for grounding.

-

Data pins for USB communication (optional).

-

Springs or solder joints ensuring physical contact and flexibility.

A quality contact must maintain low resistance (<20 mΩ) and consistent elasticity, even after thousands of compressions.

Any oxidation, dust, or plating wear can increase resistance—causing heat buildup, slower charging, and premature battery aging.

How CPG Enhances Charging Contact Reliability

CPG’s replacement charging contacts are developed to replicate OEM precision and withstand the electrical and mechanical demands of daily use.

1. Low-Resistance Design

Each pin is manufactured with high-conductivity copper alloy and nickel-gold plating, reducing voltage loss during current transfer.

2. Mechanical Durability

Spring pins are fatigue-tested for 10,000 compression cycles to ensure sustained contact pressure.

3. Thermal Stability

Contacts maintain structural integrity up to 120°C, preventing deformation during rework or soldering.

4. Anti-Oxidation Surface Coating

Prevents micro-corrosion caused by humidity and frequent plug-in operations.

5. Dimensional Precision

Pin spacing and height tolerance are controlled within ±0.03 mm for exact alignment during board installation.

Comparison: Generic Contacts vs. CPG OEM-Grade Components

| Feature | Generic Contact | CPG Charging Contact |

|---|---|---|

| Resistance | 30–50 mΩ | <20 mΩ |

| Spring Durability | 2,000 cycles | >10,000 cycles |

| Temperature Tolerance | 80°C | 120°C |

| Plating | Tin | Nickel-Gold |

| Oxidation Protection | Minimal | Advanced anti-corrosion coating |

| Alignment Accuracy | ±0.1 mm | ±0.03 mm |

This ensures consistent, low-heat, and high-efficiency charging across all supported models.

Advantages for Technicians and Distributors

-

Reduced comeback repairs caused by unstable power flow.

-

Perfect fitment—no adjustment or re-soldering needed.

-

Supports multi-brand repair lines, including Apple, Huawei, Samsung, Xiaomi, OPPO, and Vivo.

-

Batch QC reports provided for traceability and warranty coverage.

-

Easy installation—pre-tinned ends for cleaner solder joints.

For B2B clients, CPG’s standardized production and packaging ensure reliable supply consistency across large repair operations.

Typical Scenarios for Charging Contact Replacement

-

Devices with no charging response after port and cable replacement.

-

Refurbished units with weakened internal contacts.

-

Water-damaged boards where corrosion interrupts the current path.

-

Phones showing “charging pause” warnings during high-load usage.

Replacing the contact restores both charging stability and battery protection, preventing further damage to the power IC.

Selecting Quality Charging Contacts

When sourcing replacements, ensure:

-

Resistance ≤20 mΩ per pin.

-

Spring force within 50–80 g range.

-

Nickel or gold-plated finish for oxidation prevention.

-

100% electrical continuity test before shipment.

-

Clear QC documentation for after-sales tracking.

All CPG parts meet or exceed these parameters, with traceable batch certification included for professional clients.

Frequently Asked Questions (FAQ)

Q1: How do I identify faulty charging contacts?

If charging stops when pressing or bending the port area, the contacts likely lost tension or conductivity.

Q2: Are charging contacts replaceable on all phone models?

Yes, but replacement complexity varies by structure—CPG provides model-specific contacts.

Q3: Can poor-quality contacts damage the charging IC?

Yes. High resistance leads to heat buildup, which can shorten IC lifespan.

Q4: How are CPG contacts packaged for technicians?

Pre-sorted in anti-static trays with labeled part numbers and resistance test results.

Restoring the Core of Stable Charging

Every successful repair begins with a reliable power path.

With CPG’s phone charging contact replacements, repair technicians and refurbishers can restore full charging stability, reduce returns, and deliver long-term performance that customers can trust.

To explore compatible models or request quality reports, visit CPG LCD’s homepage or contact our support team through the Contact Us page.