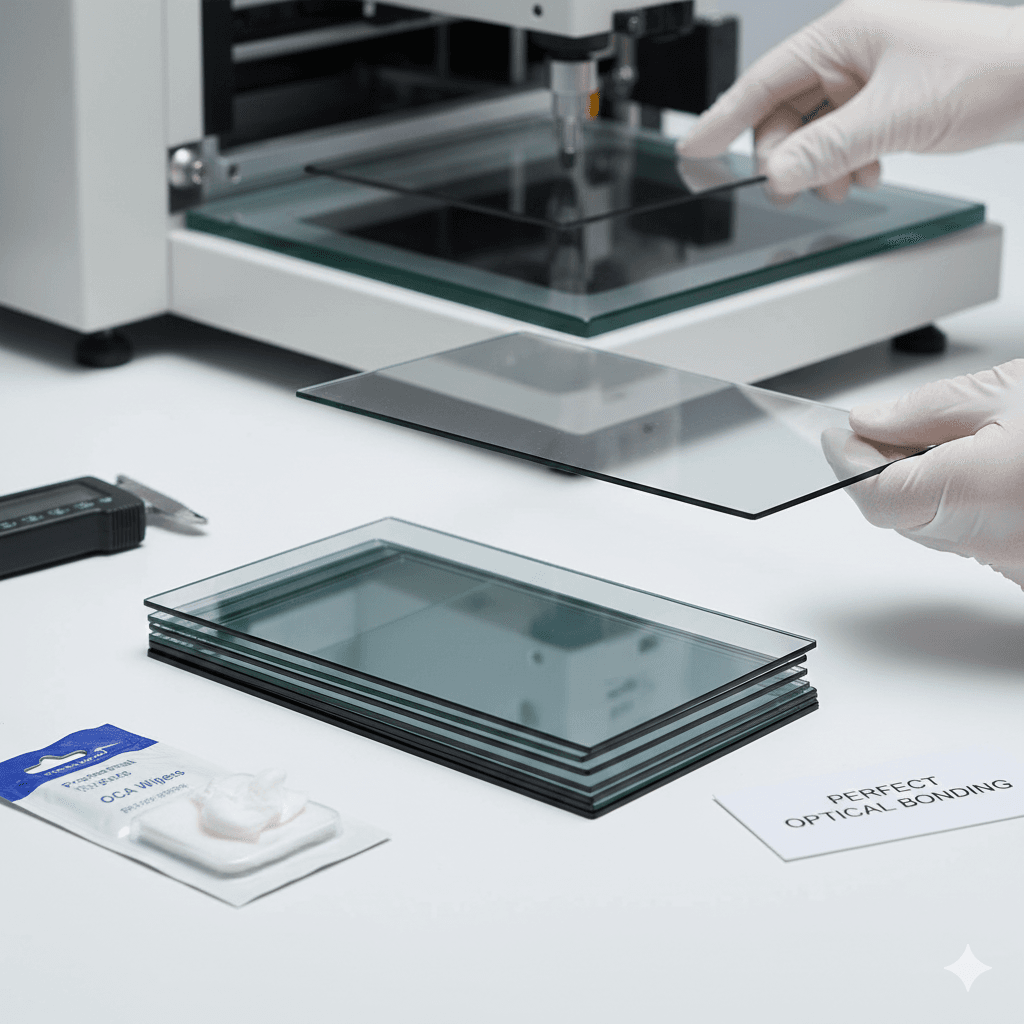

Glass Panel Compatible with OCA Laminator: Precision Bonding for Clear Display Restoration

Why Screen Restoration Fails Without Material Precision

When repairing cracked or delaminated screens, technicians often blame the laminator or OCA film for bubbles and haze.

Yet, the real issue usually lies elsewhere—the glass panel itself.

Even with premium adhesive and perfect vacuum cycles, if the panel isn’t a glass panel compatible with OCA laminator, the surface tension mismatch leads to micro air pockets, edge lift, or brightness distortion.

Common technician frustrations include:

-

Air gaps reappearing hours after curing.

-

“Rainbow rings” under sunlight.

-

Unstable lamination pressure causing edge separation.

-

Poor adhesive spread, especially on curved models.

How OCA Lamination Works and Why Compatibility Matters

OCA (Optically Clear Adhesive) lamination is a controlled process combining vacuum, pressure, and temperature to bond the display, touch layer, and cover glass.

For a perfect seal, the glass must:

-

Maintain flatness within ±0.02 mm.

-

Exhibit optical transmittance ≥95%.

-

Possess a surface energy between 35–40 dyn/cm.

-

Withstand thermal cycles up to 120°C without warping.

-

Match curvature and corner radius of the OLED/LCD module.

A true glass panel compatible with OCA laminator ensures that OCA gel flows evenly under vacuum, forming a clear, haze-free interface across the entire display.

CPG’s Precision-Engineered Solution for Perfect OCA Bonding

CPG’s glass panels are engineered from high-purity aluminosilicate glass, treated and measured for compatibility with professional OCA lamination systems.

1. Superior Flatness and Edge Precision

Every piece is CNC-ground and optically inspected to guarantee micron-level flatness.

The result: adhesive spreads uniformly, eliminating trapped air even under fast lamination cycles.

2. Consistent Optical Clarity

Each glass panel compatible with OCA laminator undergoes multi-angle light transmission testing, ensuring ≥95% brightness consistency and neutral color rendering.

3. Plasma Surface Energy Treatment

Surface treatment stabilizes adhesive wetting, preventing flow imbalance that can cause internal haze after curing.

4. Controlled Thermal Expansion

Thermal compatibility ensures alignment under heating and vacuum cycles—no warping, no micro-cracks.

Comparison: Standard Glass vs. CPG OCA-Compatible Glass

| Property | Standard Glass Panel | CPG OCA-Compatible Glass |

|---|---|---|

| Flatness Tolerance | ±0.1 mm | ±0.02 mm |

| Transmission Rate | 88–90% | ≥95% |

| Surface Energy | Uncontrolled | Plasma-balanced |

| Thermal Resistance | 80°C | 120°C |

| Bubble Rate | 10–15% | <1% (tested) |

This ensures zero-bubble lamination and long-term clarity even for curved-edge OLED displays.

Advantages for Refurbishers and Service Centers

-

High lamination yield with reduced rework rates.

-

Perfect optical alignment during bonding.

-

Batch-certified performance for large-scale refurbishing lines.

-

Compatible with major laminator brands such as TBK, G-Touch, LOK, and MECHANIC.

-

Available for all major models: iPhone, Samsung, Huawei, Xiaomi, OPPO, and Vivo.

By using CPG’s glass panel compatible with OCA laminator, technicians gain stability, consistency, and optical performance identical to factory standards.

Where OCA-Compatible Panels Make the Difference

-

Full-screen refurbishing after cracked glass removal.

-

Delamination repair of fogged or yellowed OCA layers.

-

Batch display restoration in OEM-certified workshops.

-

Curved OLED lamination, where edge sealing precision is critical.

For these demanding applications, glass precision and surface energy stability are the keys to long-term success.

Quality Control and Testing Standards

Every CPG panel undergoes:

-

Interferometric flatness measurement before packaging.

-

Optical haze and transmission testing at 550 nm wavelength.

-

Thermal cycling validation at 25°C → 120°C → 25°C (5 rounds).

-

Vacuum lamination simulation using 90°C/–90 kPa parameters.

These steps ensure ready-to-laminate quality with guaranteed yield performance.

Frequently Asked Questions (FAQ)

Q1: Can standard cover glass be used in OCA lamination?

No. Without proper flatness and surface treatment, adhesive bubbles and haze will appear.

Q2: Are CPG panels pre-cleaned and dust-free?

Yes. Each panel is cleaned, ionized, and vacuum-packed for direct use.

Q3: Are these compatible with curved-edge OLED screens?

Yes—custom 2.5D and 3D profiles are available.

Q4: What testing documentation is provided?

Optical, adhesion, and thermal resistance reports are included per batch.

Precision Bonding Starts with the Right Glass

Perfect display restoration begins before lamination.

With CPG’s glass panel compatible with OCA laminator, refurbishers can achieve flawless optical bonding, consistent transparency, and zero bubble results—bringing aged or cracked displays back to their original brilliance.

For technical specifications, model matching, or QC certificates, visit CPG LCD’s homepage or contact our support team via the Contact Us page.