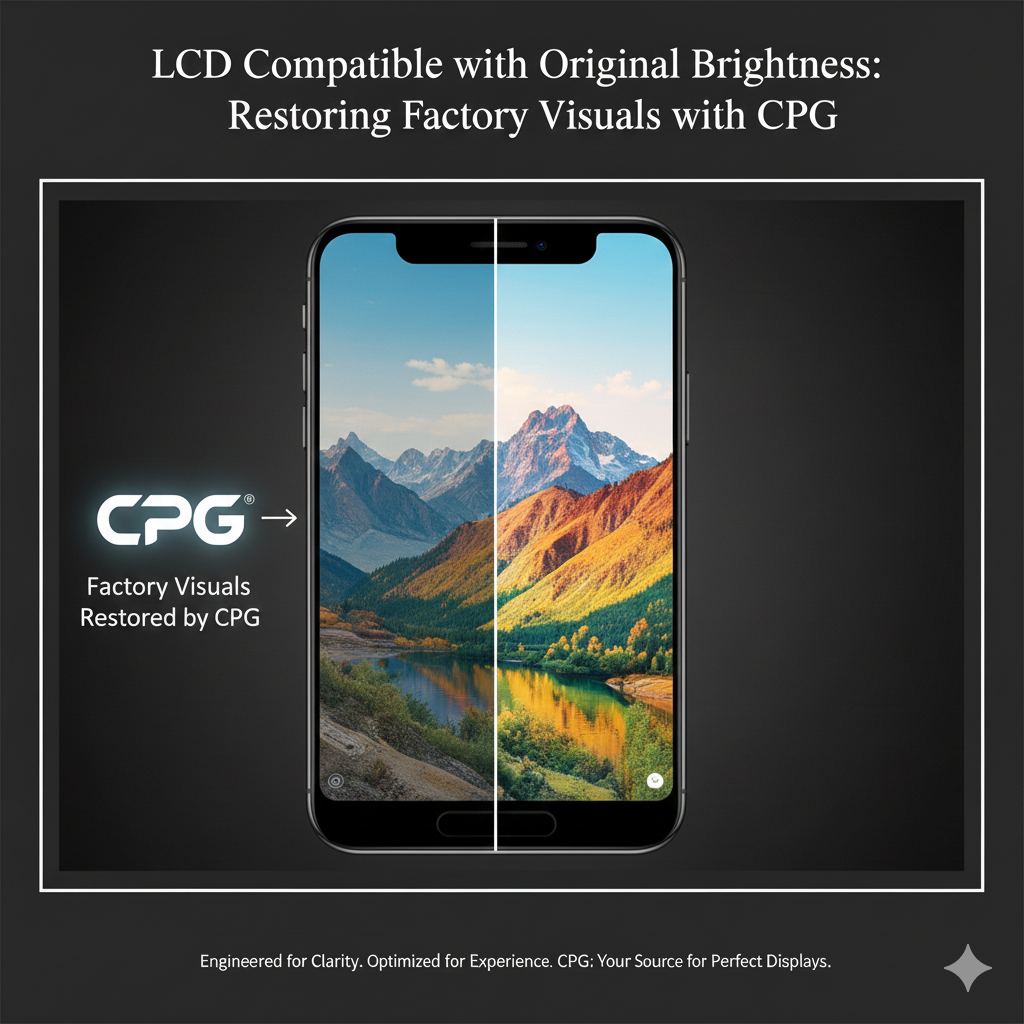

LCD Compatible with Original Brightness: Restoring Factory Visuals with CPG

When a “New” Screen Feels Dimmer Than Before

You’ve replaced the screen. The phone works again—but something feels off.

The image looks slightly dull, whites turn yellowish, and outdoor visibility drops dramatically.

This happens because brightness and backlight calibration are not just numbers—they’re the result of precise optical engineering between the LCD panel, backlight film, and driver IC.

For repair technicians and distributors, ensuring original brightness compatibility isn’t a luxury—it's essential for maintaining customer satisfaction and long-term trust.

The Science Behind Brightness Matching

A smartphone display’s brightness depends on several interconnected factors:

-

LED backlight intensity – controls peak luminance output.

-

Light diffusion and reflection layers – balance even light distribution.

-

Driver IC voltage curve – determines how efficiently brightness scales.

-

Polarizer and optical film quality – maintain contrast and color fidelity.

When a replacement LCD doesn’t match these parameters, the screen may appear either too dim or too harsh, leading to visual fatigue or battery drain.

CPG addresses this by replicating OEM voltage and optical design standards for every LCD model produced.

How Standard Replacements Fall Short

| Screen Type | Brightness Match | Color Accuracy | Energy Efficiency | Common Complaints |

|---|---|---|---|---|

| Generic copy LCD | 60–70% | Low | Poor | Dull display, uneven lighting |

| Refurbished uncalibrated LCD | 75–85% | Medium | Average | Washed-out tones |

| CPG OEM-calibrated LCD | 95–100% | High | Optimized | None – factory matched |

Generic replacements often reuse inconsistent LED arrays or mismatched polarizers, resulting in uneven luminance.

By contrast, CPG’s LCD compatible with original brightness reproduces the same visual tone curve as the factory screen—so users can’t tell the difference after repair.

CPG’s Engineering Process for Brightness Calibration

At CPG, matching OEM brightness involves a four-stage calibration and testing process:

-

Voltage Curve Mapping

Each driver IC’s current response is tuned to align with the OEM’s light emission curve, ensuring identical brightness at every level—from 10% to 100%. -

Backlight Uniformity Test

Using optical inspection systems, CPG measures brightness consistency across 16 grid zones to prevent edge dimming or hotspot glare. -

Color Temperature and Gamma Correction

White balance is calibrated between 6500–7000 K to maintain natural tones under all lighting conditions. -

Thermal Stability Simulation

Displays are tested under 40 °C–60 °C operation cycles to ensure brightness remains stable without LED degradation.

This combination ensures visual parity with original screens—down to the same luminance curve, contrast ratio, and eye comfort.

Key Advantages for Repair Professionals and Distributors

-

True-to-original brightness (95–100%), measured under controlled environments.

-

Color consistency batch-to-batch, enabling reliable resale and warranty coverage.

-

Energy-efficient LED backlights, reducing battery strain post-repair.

-

High outdoor readability, matching OEM daylight visibility standards.

-

Reduced return rates, as customers perceive no downgrade after replacement.

For repair chains, this means lower QC overhead and smoother customer experience across all device models.

Real-World Scenarios: Where Brightness Compatibility Matters Most

-

Retail service centers handling premium devices like iPhone 14 or Samsung S21, where any brightness difference affects brand perception.

-

Refurbishment programs restoring mid-range models (Huawei, OPPO, Xiaomi) for resale markets.

-

Corporate maintenance providers managing large device fleets requiring visual uniformity across screens.

In each case, CPG LCD modules deliver the precise light balance and optical comfort that users associate with brand-new devices.

Selecting the Right LCD for Brightness Matching

When sourcing LCD modules, consider:

-

Whether the supplier provides luminance test reports (cd/m²) per batch.

-

If driver IC voltage calibration aligns with OEM specifications.

-

Whether optical layers use multi-film diffusion technology for light uniformity.

-

If backlight materials are anti-yellowing rated (UV resistant) for long-term clarity.

All CPG products meet these standards, backed by internal brightness testing and traceable calibration codes.

Frequently Asked Questions (FAQ)

Q1: How close is CPG’s brightness to the original screen?

Each LCD is calibrated to achieve 95–100% of the OEM brightness curve.

Q2: Does higher brightness drain battery faster?

CPG modules use optimized LED arrays that maintain brightness efficiency without increasing power draw.

Q3: Can older phone models benefit from brightness-matched LCDs?

Yes, especially for devices with aging backlight circuits—CPG modules restore factory-level luminance.

Q4: Do you provide testing certificates for batch orders?

Yes. Every shipment includes brightness calibration and quality inspection data.

Consistent Light, Consistent Quality

Brightness defines perception—it’s the difference between a phone that feels new and one that feels tired.

With CPG’s LCDs compatible with original brightness, repair shops and distributors can ensure every replacement looks and performs like the original—no compromises, no dim displays.

To learn more about brightness-calibrated LCD modules or request a custom order, visit CPG LCD’s homepage or contact our support team via the Contact Us page.