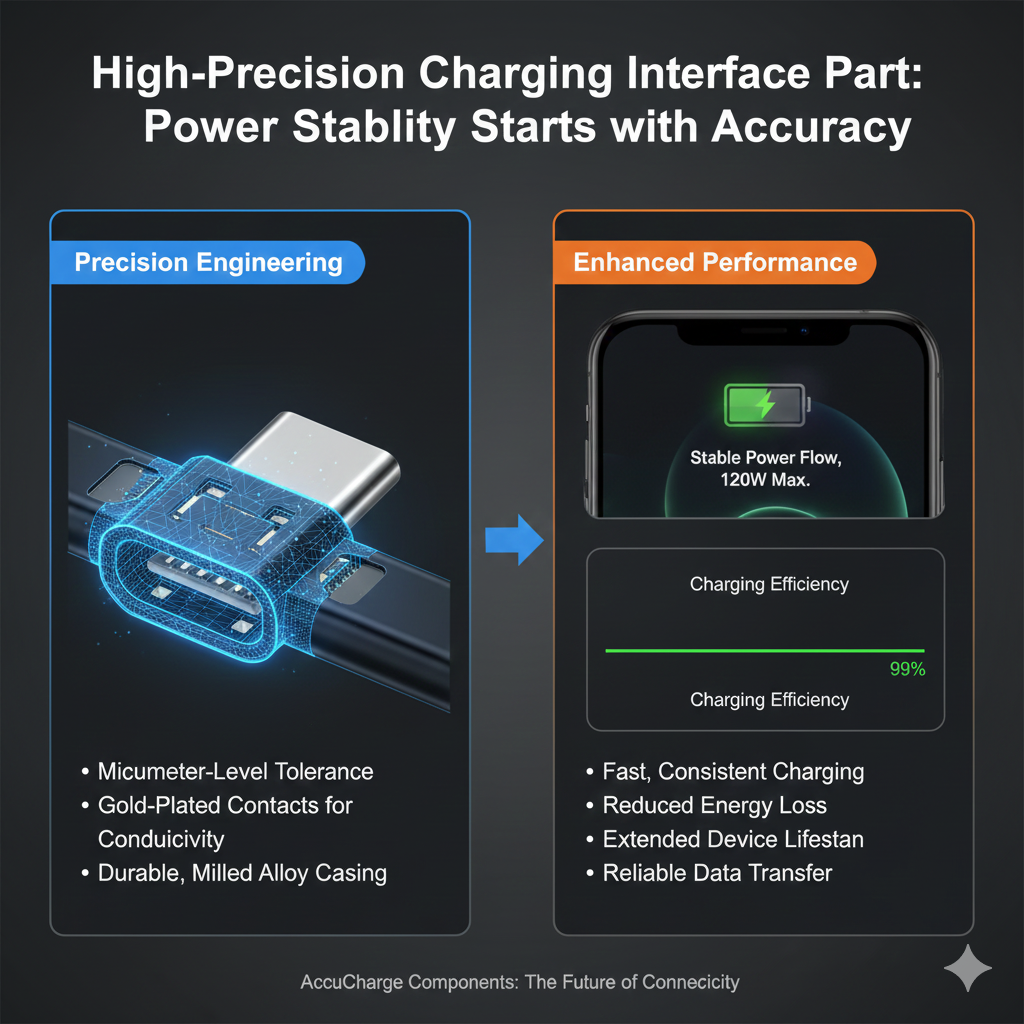

High-Precision Charging Interface Part: Power Stability Starts with Accuracy

When Millimeters Define Performance

Fast-charging devices today carry up to 6A of current through a connector no larger than a thumbnail.

At such density, even microscopic misalignment or contact resistance drift can cause:

-

Voltage drop and slow charging.

-

Excessive heat and material deformation.

-

Power negotiation errors under PD or QC protocols.

-

Long-term oxidation leading to intermittent connection.

For repair technicians and OEM suppliers, these failures often trace back to charging interfaces built with low mechanical precision.

That’s why using high-precision charging interface parts isn’t just a quality choice—it’s an electrical necessity.

Understanding the Role of Precision in Charging Interfaces

The charging interface is a mechanical-electrical hybrid component, combining conductive pins, insulating polymers, and micro-scale housing alignment.

Precision determines:

-

Contact pressure between pins and cable plug.

-

Signal path symmetry, affecting PD negotiation.

-

Thermal dissipation efficiency during prolonged fast charging.

A deviation as small as 0.05 mm in pin height or housing tolerance can introduce resistance spikes that compromise fast-charging stability.

CPG’s Engineering for High-Precision Interfaces

CPG’s high-precision charging interface parts are designed using multi-stage CNC tooling, controlled plating, and electrical validation to achieve OEM-level repeatability.

1. Dimensional Accuracy (±0.03 mm)

Each connector housing is CNC-molded and inspected under optical measurement systems for consistent fit and alignment.

2. Low-Resistance Conductive Path (<15 mΩ)

Copper alloy with nickel-gold plating ensures maximum conductivity and corrosion resistance.

3. Thermal Stability (125°C Rated)

Engineered for sustained performance during high-current fast charging without plastic deformation.

4. Power & Signal Separation Shielding

Internal EMI shielding maintains clear signal integrity and voltage stability.

5. Reinforced Solder Pads & Pin Anchors

Reduces pad detachment risk during rework or mechanical stress.

Comparison: Standard vs. High-Precision Charging Interfaces

| Parameter | Generic Interface | CPG High-Precision Interface |

|---|---|---|

| Dimensional Tolerance | ±0.1 mm | ±0.03 mm |

| Contact Resistance | 30–50 mΩ | <15 mΩ |

| Heat Resistance | 80°C | 125°C |

| PD Compatibility | Partial | Full (PD 3.1 / QC 5.0) |

| Connector Lifespan | 3,000 cycles | >10,000 cycles |

| QC Process | Visual only | Optical + Electrical + Thermal |

Such precision ensures stable current flow, consistent fast-charging negotiation, and extended component lifespan across devices.

Advantages for Technicians and Distributors

-

OEM-grade pin alignment, ensuring no loose or off-center fit.

-

Enhanced durability, suitable for high-use devices or enterprise fleets.

-

Reduced thermal load, preventing charging IC failures.

-

Comprehensive test data for every batch with traceable serial codes.

-

Available in both solder and flex-mounted versions for different repair workflows.

For distributors and refurbishers, standardized precision reduces rework, improves assembly efficiency, and enhances resale confidence.

Where High-Precision Charging Interfaces Make a Difference

-

Fast-charging smartphones using PD 3.0 / QC 4.0 protocols.

-

Gaming phones and tablets under constant high current draw.

-

Laptop and hybrid devices with USB-C power delivery input.

-

Refurbished devices requiring consistent assembly tolerances.

-

Industrial terminals exposed to repeated plug-in cycles.

Across all these environments, precision ensures not only performance—but safety under continuous current flow.

How to Choose a Reliable High-Precision Interface

When sourcing replacement parts or components, verify:

-

Rated current ≥6 A and voltage ≥20 V.

-

Contact resistance <20 mΩ per line.

-

Temperature tolerance ≥120°C.

-

Mechanical life ≥10,000 plug cycles.

-

Full PD/QC protocol certification.

CPG provides all parameters along with testing reports, CAD alignment data, and electrical validation certificates, ensuring complete transparency and traceability.

Frequently Asked Questions (FAQ)

Q1: What makes a charging interface “high-precision”?

Tight mechanical tolerances and controlled electrical resistance for consistent fast-charging and signal stability.

Q2: Does high precision affect compatibility?

Yes—in a positive way. It ensures perfect OEM fit and improved electrical connection reliability.

Q3: Are CPG connectors compatible with PD and QC systems?

Absolutely. All models are tested under PD 3.1, QC 5.0, and proprietary charging protocols.

Q4: Can these parts be used for refurbishment and OEM assembly?

Yes—they are suitable for both professional repair and mass production lines.

Precision Defines Performance

In high-speed charging, every micron counts.

With CPG’s high-precision charging interface parts, repair engineers and OEM partners can guarantee reliable current flow, safe operation, and lasting mechanical integrity—every connection built for performance and trust.

To request part specifications or QC documentation, visit CPG LCD’s homepage or contact our team via the Contact Us page.