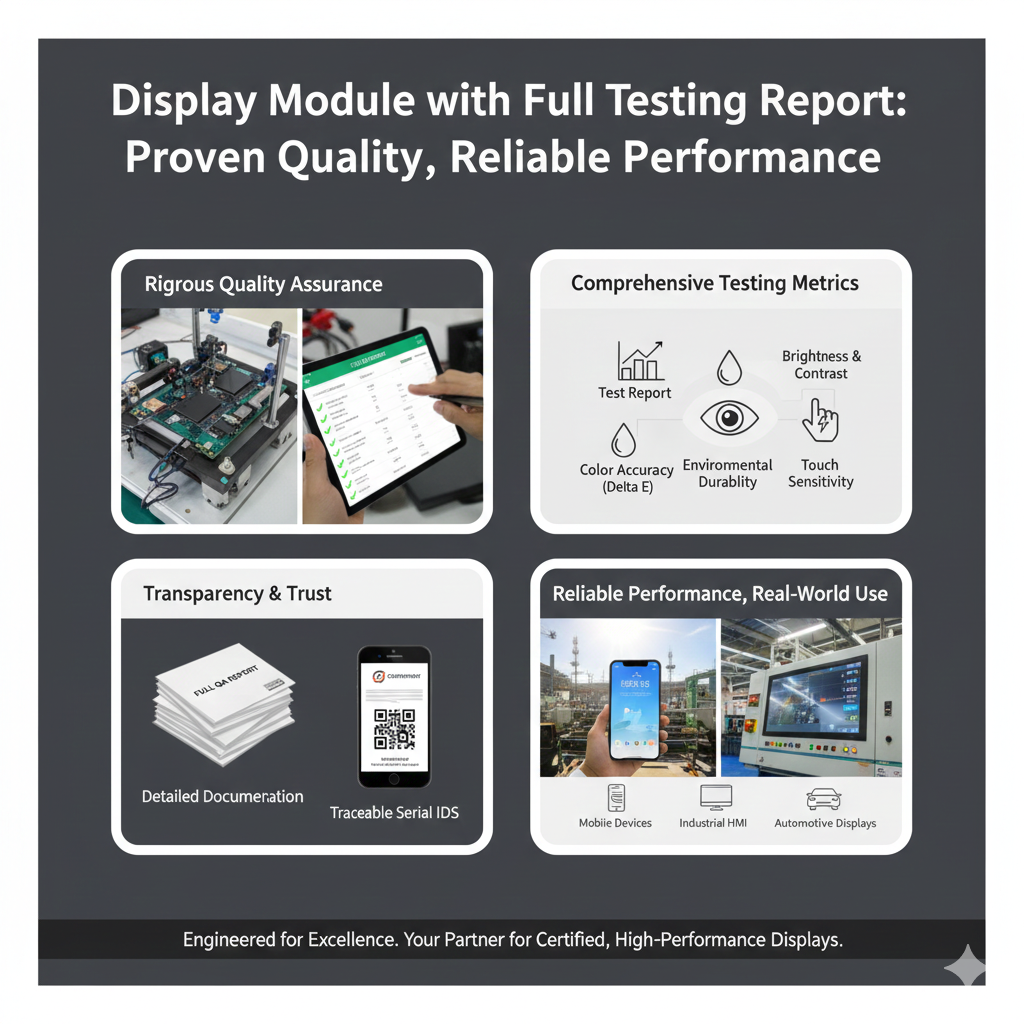

Display Module with Full Testing Report: Proven Quality, Reliable Performance

Why Repair Shops Can’t Rely on “Visual Check Only”

In the fast-moving phone repair market, it’s tempting to trust what looks new.

A clean screen, no scratches, smooth touch—that’s good enough, right?

Not anymore.

Without detailed testing data, even a flawless-looking module can hide internal inconsistencies:

-

uneven brightness between zones,

-

unstable voltage draw causing screen flicker,

-

inaccurate color balance,

-

weak bonding between digitizer and panel.

These issues don’t always appear during installation—but they often return as customer complaints days later.

That’s why a full testing report is now the standard of professionalism in the LCD replacement business.

The Science Behind a Display Testing Report

A genuine testing report isn’t just paperwork—it’s a digital record of electrical, optical, and mechanical consistency.

At CPG, every display module undergoes a five-layer inspection process:

-

Voltage & Current Stability Test

Confirms driver ICs deliver consistent brightness without energy spikes. -

Color Temperature Calibration (ΔE Analysis)

Measures color deviation against OEM standards (target ΔE ≤ 2.0). -

Backlight Uniformity Scan

Ensures brightness is evenly distributed across all zones, with <5% variation. -

Touch Sensitivity Mapping

Tests 20+ touch points for linearity, accuracy, and latency below 10ms. -

Aging Simulation Test

8-hour continuous burn-in to confirm long-term reliability under temperature and voltage stress.

The data from these procedures is compiled into a unique CPG Testing Report, traceable by serial number and shipment batch.

How Full Testing Reports Protect Both Technicians and Clients

| Verification Type | What It Proves | Why It Matters |

|---|---|---|

| Voltage & current report | Consistent power draw | Prevents overheating, battery drain |

| Brightness & color graph | True-to-original display tone | Reduces warranty disputes |

| Touch map record | Full sensor coverage | Ensures user satisfaction |

| Batch traceability ID | Supply chain transparency | Simplifies after-sales claims |

Unlike generic suppliers, CPG provides verifiable metrics per module, not just random sample tests.

Each report links directly to the shipped unit—ensuring accountability from factory to end repair shop.

How CPG’s Full Testing Reports Are Generated

CPG’s in-house QA systems use integrated optical analyzers and AI-assisted image sensors to automatically record:

-

brightness curves,

-

color gamma data,

-

voltage response,

-

IC temperature stability.

Every screen is scanned in real time, and the report is digitally archived for six months, allowing distributors and repair networks to verify authenticity anytime.

Each report includes:

-

Model code and batch serial number

-

Production date and test station ID

-

Measured luminance, color temp, touch precision, and defect logs

This level of traceability sets CPG apart as a data-driven display supplier, trusted by service networks across Asia, Europe, and South America.

Advantages for Repair Centers and Distributors

-

100% verified performance before shipment.

-

Reduced customer returns due to data-backed quality.

-

Faster troubleshooting, since every screen’s voltage and color profile is traceable.

-

Enhanced brand credibility—you can show clients proof of quality, not promises.

-

Consistent visual experience, crucial for fleet or enterprise repairs.

For wholesale partners, testing reports become a key part of after-sales risk control, protecting both business reputation and profit margins.

Practical Scenarios Where Testing Reports Matter

-

Authorized repair centers requiring documented quality control for Apple, Samsung, and Huawei devices.

-

Bulk refurbishment programs that need uniform brightness and color accuracy across thousands of units.

-

B2B distributors supplying regional partners who demand proof of calibration.

-

Corporate service contracts where screen uniformity affects brand standards.

With CPG, every display module arrives with the same confidence level as factory-installed screens—verified, documented, and ready to perform.

Selecting Verified Display Modules for Your Workflow

When choosing a supplier, ensure:

-

They provide per-unit reports, not just batch summaries.

-

Reports include optical and electrical test parameters, not visual inspection only.

-

Data is traceable by QR code or serial ID.

-

Test results are consistent across multiple shipments.

CPG fulfills all four, offering full testing documentation alongside every model—from iPhone and Samsung to Huawei, Xiaomi, and OPPO assemblies.

Frequently Asked Questions (FAQ)

Q1: What format are CPG testing reports in?

Each module includes a digital PDF or QR-based online record linked to its batch number.

Q2: Are all screens tested individually?

Yes, every single unit passes through our automated inspection system.

Q3: Can I verify the report online?

Yes. Each report includes a QR code that leads to CPG’s database for instant authenticity check.

Q4: Does the report include touch and brightness metrics?

Absolutely. Both are part of our optical-electrical testing protocol.

Transparency Builds Trust, and Trust Drives Business

In today’s competitive repair market, data-backed quality isn’t optional—it’s a standard.

With CPG’s display modules and full testing reports, distributors, repair networks, and refurbishers can finally operate with confidence, knowing that every product is verified, traceable, and fully compliant with OEM performance standards.

For documentation samples or partnership inquiries, visit CPG LCD’s homepage or reach our support team via the Contact Us page.